CRYOGENIC TECHNOLOGIES

Rameshni & Associates Technology & Engineering (RATE) offers technologies in Cryogenic Technologies from upstream, to midstream and downstream with full performance guarantees.

Cryogenics is the production and behavior of materials at very low temperatures. The branches of engineering that involve the study of very low temperatures (ultra-low temperature i.e. below 123 K), how to produce them, and how materials behave at those temperatures.

Acid gas streams, consisting primarily of hydrogen sulphide (H2S) and carbon dioxide (CO2), are commonly generated as a by-product of the gas sweetening process used to bring produced gases and solution gases up to pipeline specifications for sales and transport. The conventional methods for acid gas disposal are to have acid gas sweetening unit to have the sales gas and to use a Claus process to convert the H2S to sulphur. However, the new requirements of CO2 recovery will add the additional cost to the project.

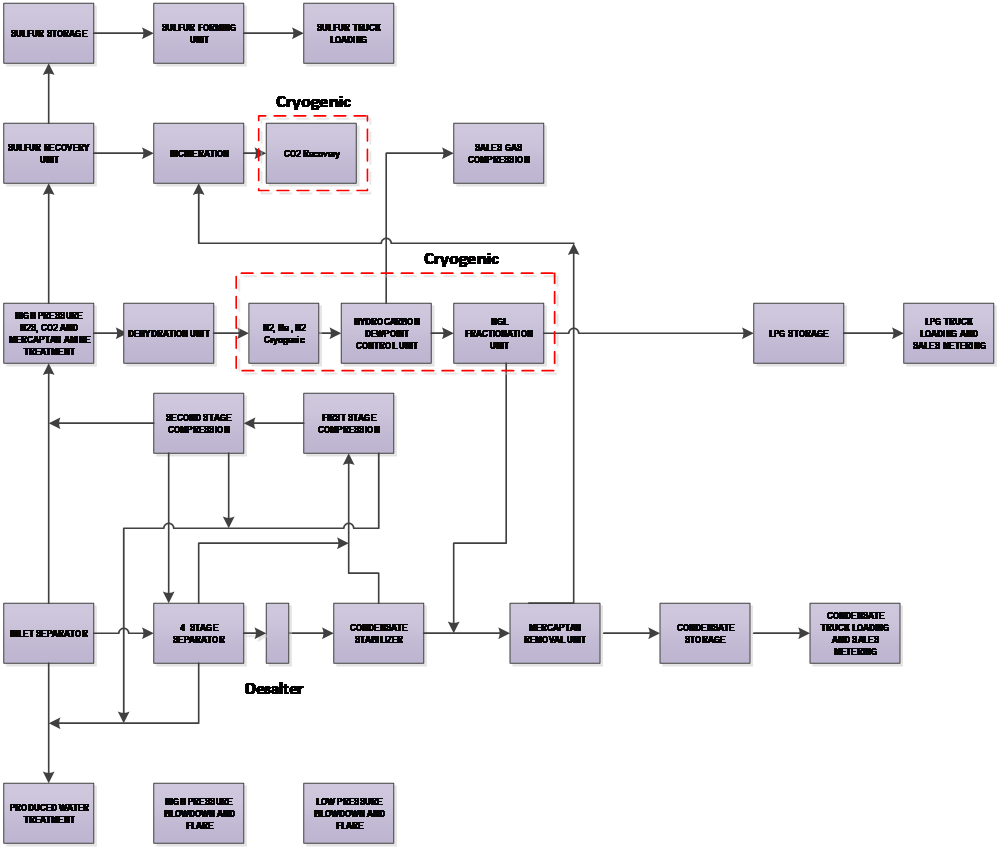

In a typical Sour Gas Field Developments with high H2S content, the common practice is to produce large quantity of sulphur. However, in order to meet the pipeline sales gas, dehydration, hydrocarbon dew point control, Nitrogen Rejection, NGL and LPG recovery are required which, the cryogenic distillation are applied. The new requirements added are CO2 recovery from stack that so called flue gas decarbonization which, could refer to CO2 liquefaction as one of the option as it is considered another Cryogenic process and in fact the most economical option.

The concept of CO2 recovery and reinjection is expanded to both H2S and CO2 recovery and reinjection, which, ultimately would meet the emission requirements for both sulphur and carbon. Even though, the H2S and CO2 reinjection shall be optimized using the advanced Cryogenic Process.

It is well known that reinjection of H2S and CO2 in a gas phase requires large compressors to inject deeply underground. Safety aspects, H2S leakage, large compressor stations costs are some of the factors shall be considered. However, using Cryogenic process, the H2S and CO2 can be converted in liquid phase, the reinjection can start using pumps.

- Pumping a low pressure liquid on surface is a lot less risky than compressing a high pressure gas.

- The high concentration of H2S advantage is that it can be easier liquefied.

- Putting the highest pressures underground under a wellhead is more reassuring from a safety manageability point of view.

RATE offers Cryogenics technologies for the following applications.

- H2S and CO2 Liquefied Reinjection

- CO2 Liquefaction and Reinjection

- Hydrocarbon Dew Point Control

- NGL Recovery & LPG Product

- LNG (Liquefied Natural Gas)

- Cryogenic Nitrogen Rejection

- Cryogenic Hydrogen Reduction

- Cryogenic Helium Recovery

- SO2 Liquefaction with or without Membrane

- Liquids streams recovered from gas processing require fractionation/distillation.

- Deethanizer tower to produce natural gas liquids a mixture of propane, butane and condensate.

- NGL fractionation into specification propane, field grade butane, LPG (mix of propane and butane), normal & iso-butane, and condensate.

- Stabilizer tower to remove the lighter hydrocarbon components from the condensate, bringing it to a specification appropriate for atmospheric storage.