First Class Design for Protection of the Environment

WASTE TO ENERGY with CO2 RECOVERY

There are refinery residuals, gases, or materials that would otherwise be disposed of as waste materials or waste streams are now required to be recovered to useful products to support the new environmental regulations.

Re-storing Energy for future environment from waste streams are designed by creating a chemical reaction that combines those carbon-based materials (feed-stocks) with air or oxygen, breaking them down into molecules and removing pollutants and impurities and sulphur has to be recovered.

Waste recovery plants are designed differently from other type units and due to environmental regulation investors are trying to convert such waste streams to useful product and accepting the challenges.

Waste-to-Energy or Energy-from-Waste is the process of generating energy in the form of electricity and/or heat from the primary treatment of waste, or the processing of waste into a fuel source. Waste to Energy is a form of energy recovery.

Wet waste, solid waste, and gaseous waste streams are potential high-impact resources for the domestic production of biofuels, bio product precursors, heat, and electricity. Wastes represent a significant and underutilized set of feed stocks for renewable fuel and product generation.

These streams are available now without land-use change and in many cases their utilization helps to address the unique and local challenges of disposing of them. These resources are unlikely to diminish in volume in the near future, and as a result (in the short and medium term), they represent a potentially low-cost set of feed stocks that could help justify broader investment.

The potential of the following waste streams:

- Commercial, institutional, and residential food wastes, particularly those currently disposed of in landfills

- Commercial, institutional, and residential food wastes, particularly those currently disposed of in landfills

- Commercial, institutional, and residential food wastes, particularly those currently disposed of in landfills

- Organic wastes from industrial operations, including but not limited to food and beverage manufacturing, biodiesel production, and integrated biorefineries, as well as other industries such as pulp and paper, forest products, and pharmaceuticals

- Biogas derived from any of the above feedstock streams, including but not limited to landfill gas.

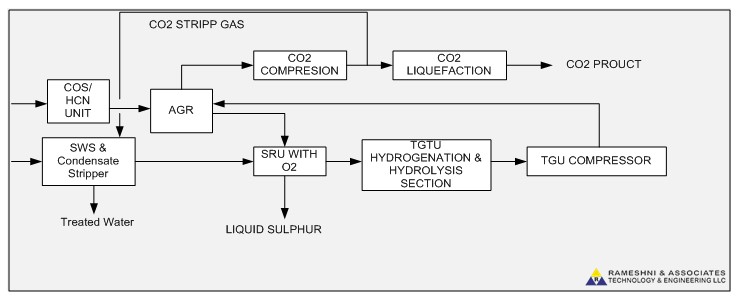

- COS/HCN Hydrolysis

- AGRU design with physical solvent

- CO2 Recovery

- Sour water stripping and Condensate

- Sulphur recovery technology with 100% oxygen enrichment and TGTU

- TGTU Recycle to AGRU

- Zero H2S, SO2, CO2 Emissions

- Backup Incineration system

There at three variations of mini-refineries where the waste is converted to energy.

- A simple topping refinery

- A simple topping refinery

- A hydro skimming refinery with naphtha and diesel hydrotreaters and naphtha reformer

Option 1 – For the simple topping refinery, the configuration consists of a gas fired heater to heat the crude before the atmospheric distillation unit refers to Topic Mini-Refinery.

Option 2- For the simple topping refinery, the configuration consists of a gas fired heater to heat the crude before the atmospheric distillation unit refers to Topic Mini-Refinery.

Option 3 – For the hydro skimming refinery with naphtha and diesel hydrotreaters and naphtha reformer the scheme consists of option 2 minus the hydrogen plant plus a naphtha reformer. The hydrogen plant is not needed due to the naphtha reformer providing hydrogen for the naphtha and diesel hydrotreaters.