First Class Design for Protection of the Environment

NATURAL GAS DECARBONIZATION with

CO2 LIQUEFACTION & 2-STAGE MEMBRANE

Rameshni & Associates Technology & Engineering (RATE) has the unrivalled ability to address all sulphur removal and handling issues across all industry sectors.

In recent years there have been many developments in LNG, Shale gas and others where it is required to remove CO2 from natural gas. The recovered CO2 is compressed and re-injected to reduce the CO2 emission. Producing high purity dry CO2 is always a challenge with the conventional process. Dry high purity CO2 is usually required to either reinject or for other usage.

Industry players have been focusing on developing new and more efficient carbon capture technologies and processes.

EOR activities dominated the global application demand while accounting for around 80% of the total revenue in 2015. Depleting production rates in conventional oil reserves along with increasing reliance on crude oil imports primarily in the Asia Pacific has led to the growth of gas injection EOR techniques. With the increasing fossil fuel demand, the demand-supply gap is also widening.

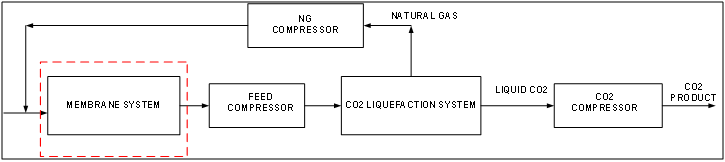

MTR and RATE are working together where MTR designs the membrane systems and RATE designs the CO2 liquefaction downstream of membrane. The advantage of using liquefaction system downstream is to reduce overall recycle of CO2 to feed of the membranes. The advantage of using membranes is to maximize hydrocarbon recovery in first stage and avoid losing ethane and heavy hydrocarbons to liquefaction. This has significant advantage of not forming ethane and CO2 azeotrope which is difficult to break in a standalone liquefaction systems. The combination of membranes and liquefaction system can produce up to 99%+ pure dry CO2.