First Class Design for Protection of the Environment.

SOUR WATER STRIPPING – SWS.

Rameshni & Associates Technology & Engineering (RATE) offers Licensing technologies in sour water strippingfor upstream, to midstream and downstream with full performance guarantees. RATE offers valid patented technologies that are grantedto RATE by USA Patents and Trade Mark Office.

In refineries, the sour water is produced from different units like the Naphtha and Diesel Hydrotreating and the Delayed Coker units.

The sour water stripper removes hydrogen sulfide and ammonia from the sour water generated in the refinery. Steam, generated in the reboiler, heats the water and strips the hydrogen sulfide (H2S) and ammonia (NH3) from the water.

The sour water streams produced by the Distillations and Delayed Coking units often referred as phenolic water. While the sour water stream produced by the Hydrotreating Units, often referred as non-phenolic water.

The sour water from the Delayed Coker contains H2S, NH3, and CO2, water, phenol and cyanide. The sour water from the Hydrotreater contains H2S, NH3, CO2 and water.

In other words, In addition to ammonia, hydrogen sulphide, and carbon dioxide, phenolic sour water may contain a host of so-called heat stable salts (HSSs), hydrogen cyanide, and phenols. The presence of these components can adversely affect the ability to strip ammonia and H2S.

Due to solubility of ammonia in water, and other impurities, design of phenolic sour water stripper are different than non phenolic sour water stripper.

- Bigger Reboiler with higher Reboiler Duty

- More trays or higher efficiency trays

- Phenolic treated water cannot be used as process water, damage hydrotreater catalyst

- The overhead system of phenolic and non phenolic SWS may be designed differently to prevent the buildup in the SWS

- RATE Single Stage Sour Water Stripping Non-Phenolic Water

- RATE Single Stage Sour Water Stripping Phenolic Water

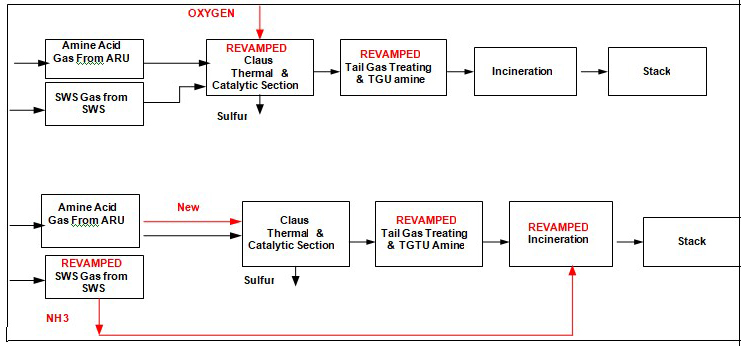

- Special Design in SRU Reaction Furnace and high intensity burner for ammonia destruction

- SRU Ammonia Destruction philosophy and burner management control system

- SRU Ammonia Burning with air or oxygen

- SRU High Ammonia Burning with high level of oxygen enrichment

- Destruction of ammonia, Cyanide, heavy HC & BTEX, & mercaptans in the SRU

- SW-MAX, Two Stage sour water stripper produce pure NH3 and Pure H2S

- SW-MAX, Two Stage sour water stripper with ammonia burning incineration

- SWS design modification for capacity expansion

- SWS design revamp from one stage to two stage

- SWS design revamp to capture impurities

The stripped water must comply with the following specifications in the design case:

- Maximum H2S content (wt ppm): <1

- Maximum NH3 content (wt ppm): 10