First Class Design for Protection of the Environment

COKE OVEN GAS SULPHUR TECHNOLOGIES

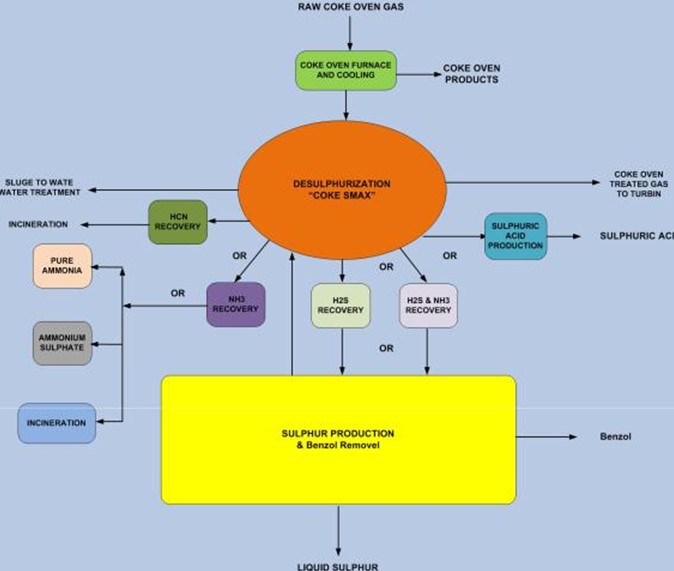

Rameshni & Associates Technology & Engineering (RATE) has the unrivalled ability to address all sulphur removal and handling issues across all industry sectors. In the Steel Plant, Coke Oven Gas after removal of impurities will be used as a fuel in the Integrated Steel Plant as well as for heating of Coke Oven Battery. Removal of Ammonia & Hydrogen Sulphide from Coke Oven Gas is technological environmental necessity. The variation amount of ammonia, HCN, H2S and CO2 which are the main components from the Coke Oven and they are required to be processed in the most feasible and economical ways ultimately producing sulphur.

The main objective of the shale oil co-product Semi-Coke Gas (SCGU) is

discussed as follows:

• Combustion of semi-coke gas

• Combustion of shale gasoline

• Sulphur removal from semi coke gas before combustion and/or from

• flue gas after combustion

• Production of electrical power

For such specific demand, RATE has developed “COKE-SMAX” technologies which consist of the producing the coke oven treated gas for power or energy use, separation of H2S and ammonia from coke oven gas. It is based upon NH3 absorption of H2S and liquid regeneration by steam stripping in a still column by using ammonia solution. “COKE-SMAX” is the most cost effective option where it utilizes aqueous ammonia as the absorbing solution to remove sulphur from coke oven gas. Absorbing solution from the bottom of the hydrogen sulphide absorber is pumped to the deacidifier. Acid gases from the top of the deacidifier, containing hydrogen sulphide, ammonia, hydrogen cyanide, and carbon dioxide, are sent to an absorber where ammonia is selectively removed.

For such specific demand, RATE has developed “COKE-MAX” technologies which consist of the producing the coke oven treated gas for power or energy use, separation of H2S and ammonia from coke oven gas. It is based upon NH3 absorption of H2S and liquid regeneration by steam stripping in a still column by using ammonia solution

RATE CAPABILITIES, & QUALIFICATIONS – COKE OVEN GAS

- Acid Gas Removal

- Acid Gas Removal

- NH3 Removal

- HCN Remova

- Benzol Removal

- Sulphur Recovery and Tail Gas Treating Systems

- 100% Oxygen Enrichment Claus

- Conventional Tail Gas Treating with or without tail gas amine portion

- Un-Conventional Tail Gas Treating such as Caustic Scrubber

- Recycle Quench OVHD to COKE SMAX Processes