Liquefied Acid Gas Injection

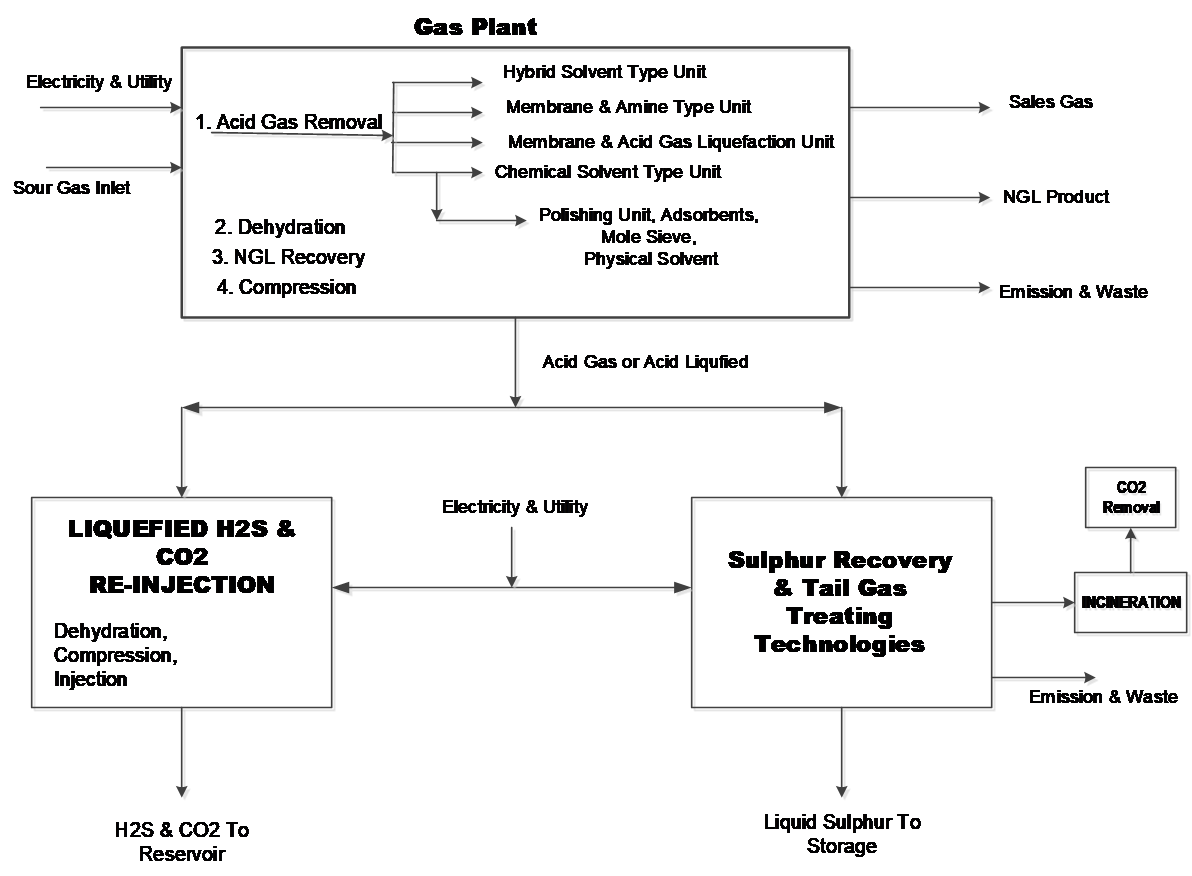

Rameshni & Associates Technology & Engineering (RATE) offers technologies in Acid Gas Reinjection and Liquefied Acid Gas Reinjection Technologies from upstream, to midstream and downstream with full performance guarantees.

A novel way to dispense with sulphur recovery and tail gas treating is to inject the acid gas into saline aquifers and depleted gas/oil reservoirs. Acid gas injection (AGI) has now been widely practiced by the oil and gas industry. This eliminates the need to upgrade or build ever more expensive sulphur recovery facilities as the environmental regulations tighten. However, reinjection in liquid form are easier, safer, and requires less capital and operating costs.

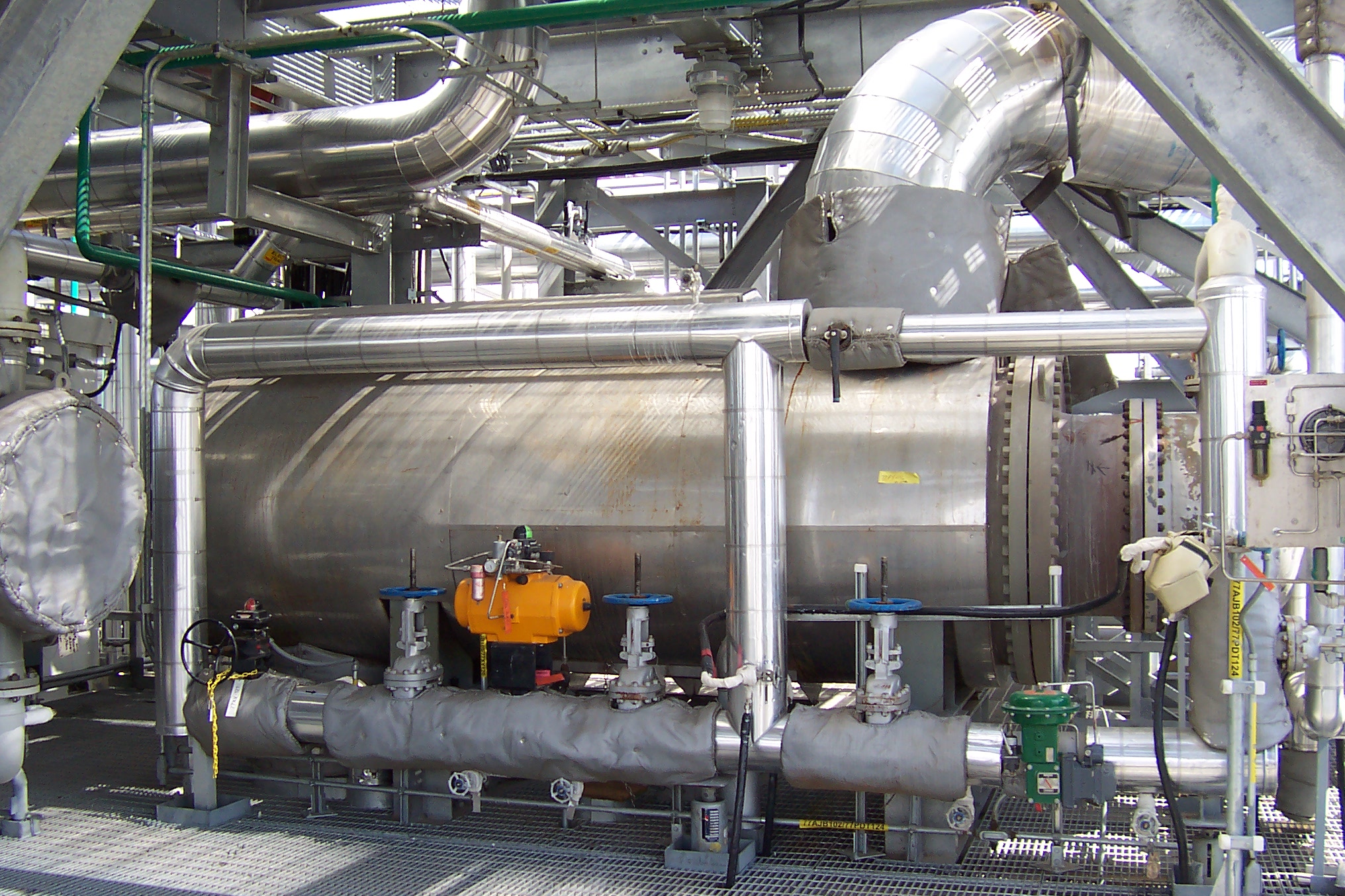

The Acid Gas or Liquefied acid gas reinjection involves three steps: separation and pumps & compression, dehydration and injection.

Some gas fields contain very high amounts of H2S (more than 30 vol%) or CO2 (up to 70 vol%) in natural or associated gases. The purification can be advantageously carried out by a cryogenic process. However, the thermodynamic behavior of natural gases containing H2S and CO2 becomes very complicated in the low temperature zone, mainly because CO2 may crystallize and H2S may cause liquid immiscibility.

Cryogenic distillation processes offer many advantages when the separated acid gases need to be re-injected, to limit undesired sulphur production or to minimize greenhouse gases emissions to the atmosphere. They are very selective towards light hydrocarbons, and the separated acid gases (H2S and/or CO2) are recovered in the liquid state under pressure. Producing the acid gases as a high pressure liquid saves expensive and energy consuming compression requirements, because the pumping duty is much lower.

For high content of H2S, the configuration of membrane followed by the acid liquefaction will result the lowest capital and operating costs and will provide much more safer operation by using pumps, in addition, significant reduction on the utility consumptions compare to other acid gas removal options.

Reinjection of H2S and CO2 in the liquid phase provides significant safety features and reduces safety concerns in addition it reduces the capital and the operating costs and reduces mega size compressors station and the electricity consumption. Liquefied H2S and CO2 reinjection is an alternative to large sulphur plants.

CO2 liquefaction that has important role in CO2 recovery. Some other Cryogenic process such as hydrocarbon dew point, H2 Reduction, Helium Removal, Nitrogen rejection have important role to meet the new sales gas specification. Resulting the importance of Cryogenic distillation technologies has become essential.