Sulphur and Carbon Management Solutions in LNG Production

RATE Offerings & Capabilities in LNG

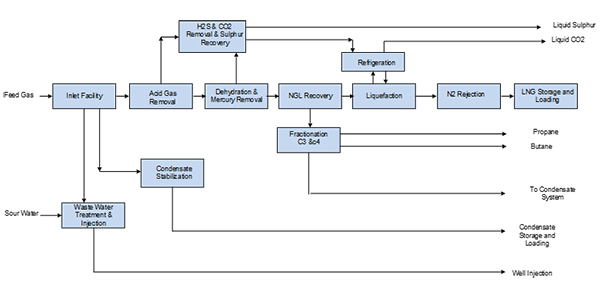

RATE is a leader in providing advanced engineering solutions for Liquefied Natural Gas (LNG) projects. We specialize in technologies that ensure efficient gas processing, sulphur management, CO2 removal, and zero-emission operations, helping clients meet stringent environmental regulations while optimizing performance and sustainability.

Liquefied Natural Gas (LNG) involves cooling natural gas to approximately -162°C to convert it into a liquid form for easier storage and transportation. A critical component of LNG production is CO2 removal, which is essential to meet product specifications, prevent corrosion, and minimize environmental impact. At RATE, we leverage our expertise in sulphur technology, gas processing, and decarbonization to deliver tailored solutions for LNG facilities, from upstream production to midstream processing. Our innovative CO2 removal and CO2 liquefaction technologies are designed to achieve efficient decarbonization and support zero-emission goals.

World energy sources have evolved during the last two hundred years from a reliance on more carbon intensive fuels to less carbon intensive fuels; from wood with a carbon intensity of about 1.25 (i.e., carbon to hydrogen atoms ratio) to natural gas (methane) with a carbon intensity of 0.65. LNG provides the means of moving energy from a remote area to a consumption center increases.

Traditionally there have been four basic options considered to utilize offshore and remote gas production and transport it to markets or to another location for further processing or utilization:

- Gas gathering and transmission to shore, in a gaseous phase, by pipeline;

- Volume reduction through either liquefaction or compression (LNG, CNG) followed by marine vessel Transportation; these types of LNG plants are referred to as ‘Base Load’;

- Conversion to other products, by changing the “methane” molecule (methanol, synthetic crude), followed by marine vessel transportation to markets;

- Conversion to other energy form such as electric power and transmission by a subsea cable to shore.

LNG is a compact energy carrier that can be transported globally in fleets of dedicated ships. By lowering the temperature of natural gas to sufficiently low temperatures the gas condenses to liquid phase. At atmospheric pressure LNG is formed at -162°C – the boiling point of methane. This liquefaction process increases the energy density (in terms of volume) by a factor of 600 and allows it to be cost effectively transported to market.

Lean Acid Gas would cause Un-Stable flame Temperature, Low temperature for HC destruction would cause Plugging, Lower recovery, Carbon lay-down on the catalyst. Shorten catalyst life and finally Unscheduled plant shutdown.

- Direct catalytic stages without thermal section, Patented by RATE

Eliminate the reaction furnace and the burner, with Claus or sub dew point stages up to 30% H2S concentration - Provide Acid Gas Enrichment before the Claus

Full Acid Gas Enrichment or common regeneration with the tail gas unit - Acid gas feed preheat and combustion air preheat

Preheating acid gas feed and combustion air will certainly help to increase the flame temperature of the Claus reaction furnace. - Supplemental fuel gas burning

Supplemental fuel gas burning is a technique often employed to raise the flame temperature while processing acid gas feed of low H2S concentrations in a sulphur plant. - Staged Oxygen Enrichment Technology

Oxygen enrichment technology is an ideal technology for raising the flame temperature of the Claus reaction furnace especially for acid gas of low H2S concentration, if oxygen is available. - RICH MAX partial acid gas enrichment in TGU, patented by RATE

Partial acid gas is sent to TGU absorber - Acid Gas bypass

- Hydrolysis Reactor after the hydrogenation reactor in the TGU, patented by RATE

We offer technologies to meet current and future environmental regulations, providing sustainable solutions that push the boundaries in sulphur technology and decarbonization for LNG projects.

Technology Innovations & Patents

RATE holds numerous patents in gas processing, sulphur recovery, and decarbonization, including innovations that enhance LNG plant efficiency, CO2 management, and reduce environmental impact. Our commitment to innovation ensures your LNG operations benefit from cutting-edge, reliable technologies.

We Strive with Technology, Innovations, and Leadership to deliver exceptional value in the LNG sector.