First Class Design for Protection of the Environment

TAIL GAS TREATING SYSTEM- TGTU

Rameshni & Associates Technology & Engineering (RATE) offers Licensing technologies in sulphur technologies and tail gas treating for upstream, to midstream and downstream with full performance guarantees. RATE offers valid patented technologies that are grantedto RATE by USA Patents and Trade Mark Office.

The SO2 reduction can be implemented incremental at each facility over the years to reduce the SO2 emission to less than 10 ppmv.

No pre-investment would be required, the budget can be allocated only on the current emission.

From 3 Tons/day to 2500 Tons/day SRU and TGU in single train

RATE TG1 – Conventional TGTU with generic solvent

RATE TG – Design of TGU with low temperature catalyst for hydrogenation reactor or inline burner

RATE TG – Design of TGU with one or two stage Quench System

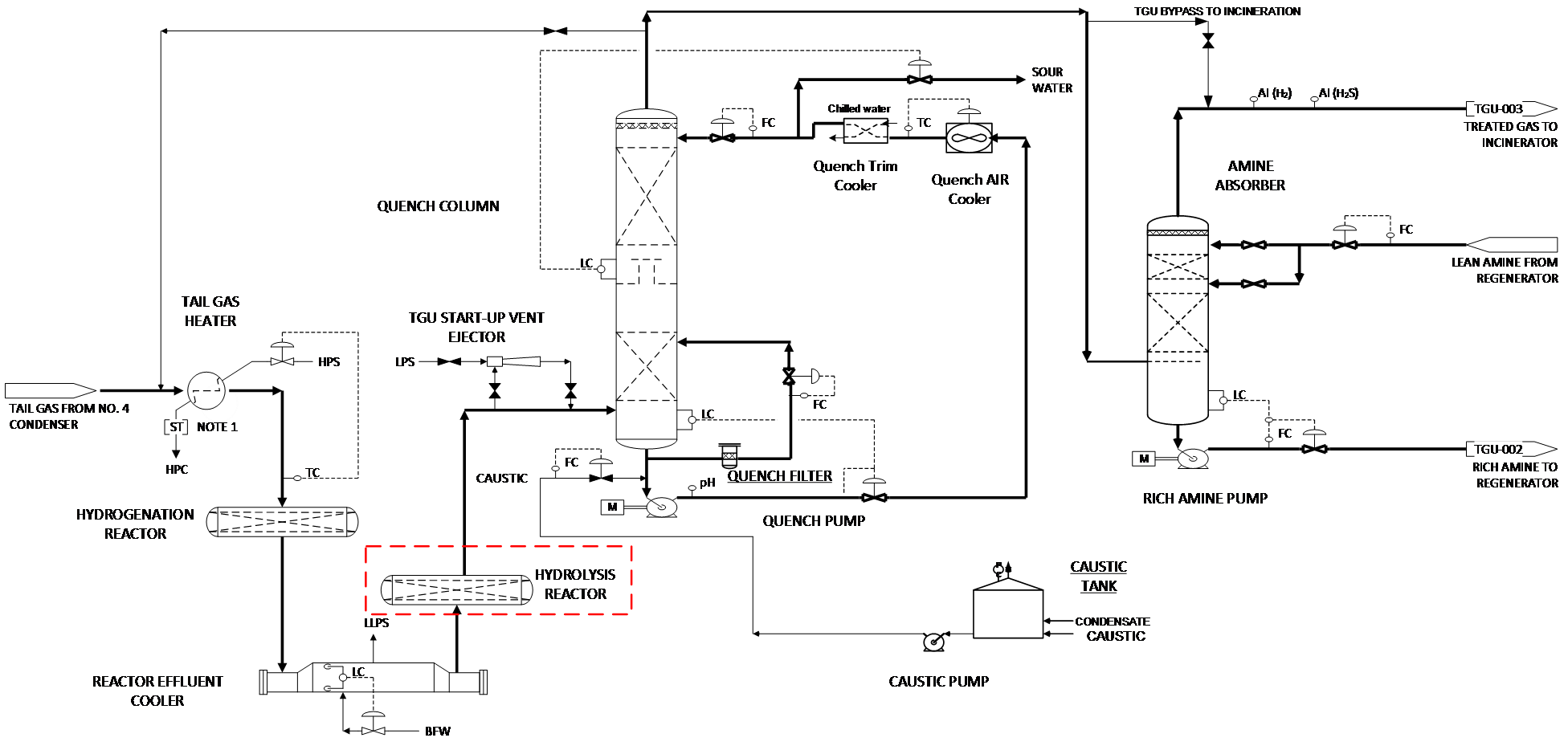

RATE TG-MAX – Conventional TGTU with formulated solvent and hydrolysis Reactor

TGTU revamp for capacity increase, change of solvent, reduce emission

TGTU revamp to comply with SRU oxygen enrichment and capacity expansion

- RATE TG-MAX2 – Conventional TGTU with formulated solvent and hydrolysis Reactor and pit vent recycle to SRU or TGTU

- TG-Caustic – Back up tail gas treating unit before stack

- RATE-Caustic, after TGTU, SMAX, SMAXB, SuperSulf and before stack

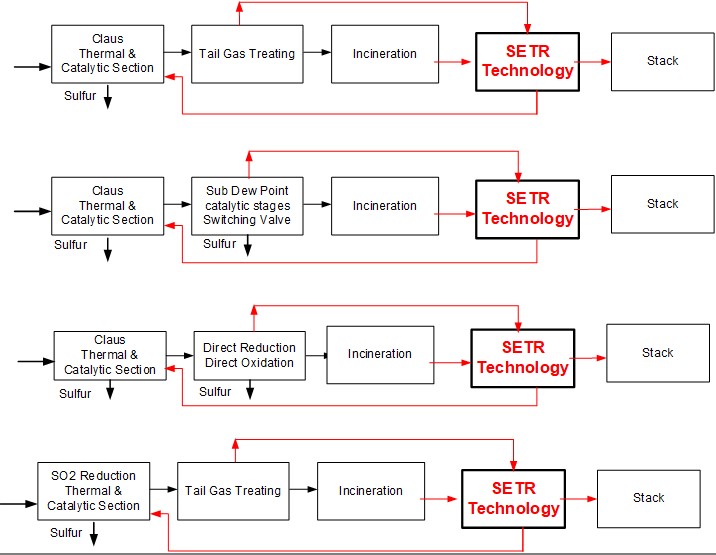

- SETR – Super Enhanced Tail Gas Recovery, after TGTU, SMAX, SMAXB, SuperSulf and before stack

- Tail Gas Incineration system after any type of Tail gas Unit

- Tail Gas Incineration with heat recovery and fuel consumption optimization

- Tail Gas Incineration with heat recovery and fuel consumption optimization

- Tail Gas Incineration design with oxygen to reduce CO2 emission

- Tail Gas Incineration design to process pure ammonia from 2-stage SWS

- Tail Gas Incineration design to process pure ammonia from 2-stage SWS

- SO2 vent from vent system to SRU or TGTU

TAIL GAS HYDROLYSIS REACTOR

TG-MAX is the patented technology by RATE

To Meet overall recovery of SRU & TGU to 99.99% or SO2 emission less than 50 ppmv.

the pit vent is recycled to the sulphur recovery reaction furnace.

RATE COS / CS2 hydrolysis reactor in the Tail Gas Unit (TGU), is an additional reactor after hydrogenation reactor to maximize the hydrolysis of COS and CS2 and to minimize the SO2 emission.

The advantage is to eliminate the caustic scrubber after the incineration.

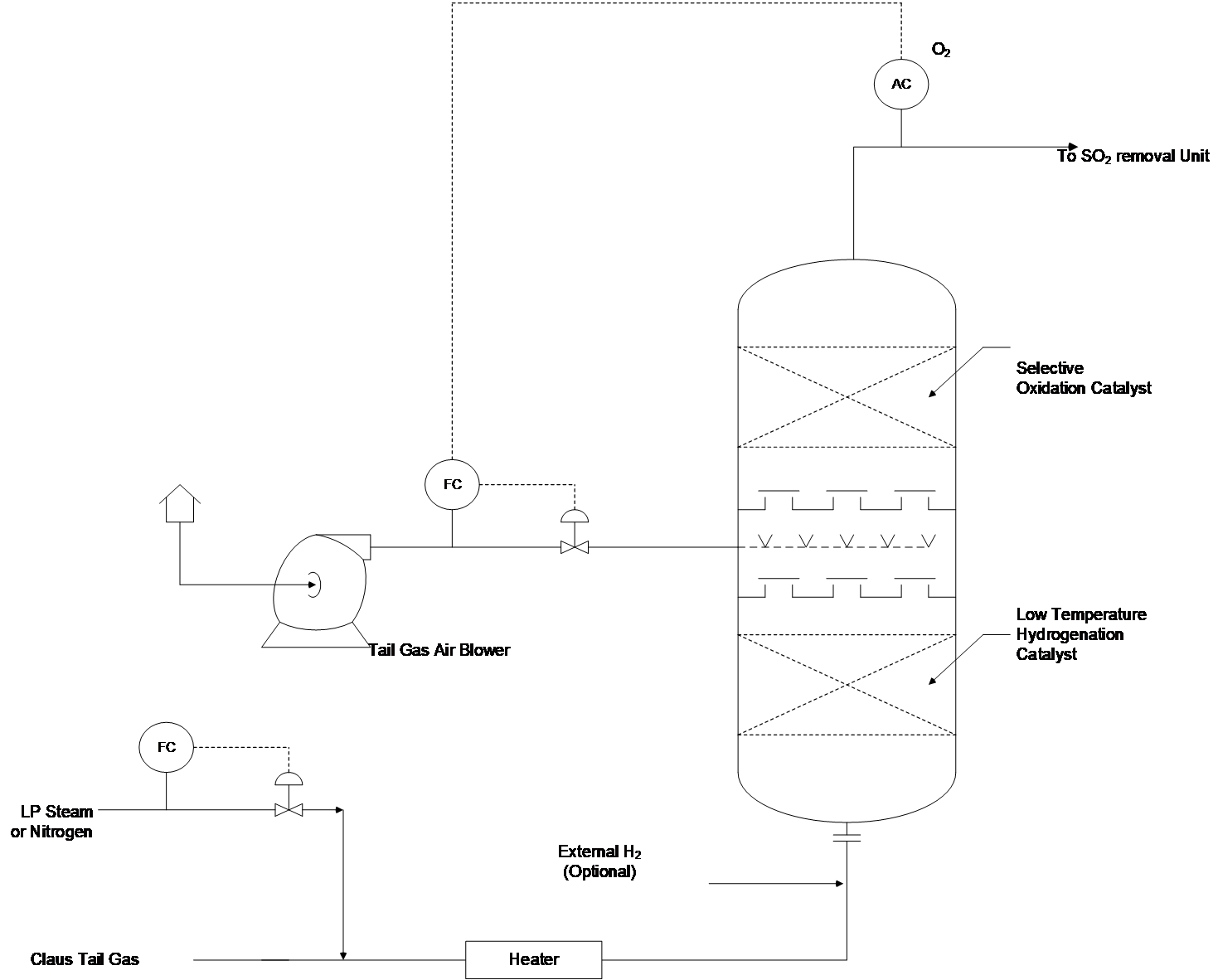

CATALYTIC TAIL GAS INCINERATION MAX (CTI-MAX)

CTI-MAX is another catalytic tail gas incineration compromising of using TGU low temperature catalyst and selective direct oxidation catalyst.

The existing sulphur recoveries are 3 stage Claus, and 3-stage Claus with direct oxidation similar to SMAX. Adding CTI-MAX and to produce ammonium sulfate type product is attractive because the product can be sold. Both ammonia and SO2 will not be wasted.

RATE licenses 2-stage sour water stripper with high purity ammonia as well as CTI-MAX.